Many importers have demand to customize their own brand of LED strips, or have special projects that require customized LED strips. You must have experienced this: Checkingthe same specifications strip with different suppliers, while you will get different price, some high and some very low. It is hard to know how to choose it, if you just choose the supplier based on the price, you may make irreversible mistakes and get products that do not meet your standard. What is the reason for this so big differenceon prices? How to choose? Which price is the most realistic price close to demand and quality? In order to find the answer and avoid the above problems, you must know the following 6 suggestions for customized led strip.

- 1.LED raw material is one of the key factors determining the price

- 2. FPC also have different class

- 3. Different production and processing methods also affect prices

- 3. Unclear demand details and price differences

- 4. Operating costs determine profit margins

- 5. Quality standards also affect costs

- 6. Find the customized product that suits you best.

The choice of LED raw materials is the most important

- LED flexible light strip is composed of two key modules: FPC and LED, while LED is composed of gel phosphor, gold wire, LED chip, and LED lead frame. The choice of each part has an impact on product quality and price.

- LED phosphor is generally synthesized by AB glue + YAG phosphor + diffusing powder. The concentration of the phosphor determines the color of white light, the color with high concentration is yellow-red, and the color with low concentration is blue-white. There are also many types of phosphors. Various phosphor are corresponding products, such as highlights, high color rendering, and beautiful spots. However, each powder has its advantages and disadvantages, and sometimes it is often necessary. Add a variety of phosphor to achieve the effect you want, at this time you need to accumulate experience.

- The function of LED phosphor is to combine light and color to form white light, the white LEDs are generally use blue color chips with yellow phosphors to emit white light.

- Cheaper phosphor after long time use, the led easy to vulcanized , also color will swift, specially used it used outdoor or poor environment.

- Phosphor powder manufacturers on the market include the United States’Intematix, Japan’s fundamental chemistry, China’s Borui, good quality and relatively high prices. Poor quality phosphors will result in poor color consistency, reduced brightness, and low cost.

- Gold Wire

- Gold wires have copper, aluminum or alloy wires , they are relatively inexpensive with poorstability, poor connection.

- Good gold wire with high purity of 99.9%, diameter of 1.0UM or higher, high heat resistance and stability, and relatively high price

- LED chip

- Domestic chips, Taiwan chips, and imported chips (including US chips, Japanese chips, German chips, etc.)

- 1. Choose different brands of chips, the price varies greatly. At present, the most expensive chips are American chips, followed by Japanese chips and German chips. The affordable ones are Taiwan chips such as wafers and chips, and the performance is also good. The decent domestic chips are relatively inferior in quality and cheap in price. Counterfeit brand chips and unknown chips have the worst quality and low price

- 2. Choosing the same brand and same model chip price will also vary. Because the chip size of the same model will be different.

- LED lead frame

- At present, there are iron frames, aluminum frames, brass frames, copper frames, etc. Aluminum LED frames are the cheapest, then brass, and finally copper. Iron frames have the worst thermal conductivity, aluminum and brass second, and copper is the best. The effects of ledframesof different materials on LED performance are also different, especially the effect on light attenuation is particularly prominent. This is mainly because the thermal conductivity of copper is much better than iron and aluminum. The thermal conductivity of copper is 398W (m.k), while the thermal conductivity of iron is only about 50W (m.k), which is only 1/8 of the former.

- FPC material:

- FPC have double layout PCB and single layout PCB. The top and bottom withcopper layersare covered with PI film. For the copper layer, it enhances tension, high toughness and resistance to bending. Copper thickness normally have 3 types: 1oz> 35um, 2oz> 70um, 3oz> 105um. Thicker copper with less voltage drop, higher electrical conductivity and better thermal conductivity, while too thicker copper will affect its flexibility, special for the strip with more component, with many co Single panel only has PI film on the bottom layer, no PI film on the top layer but coated with white oil

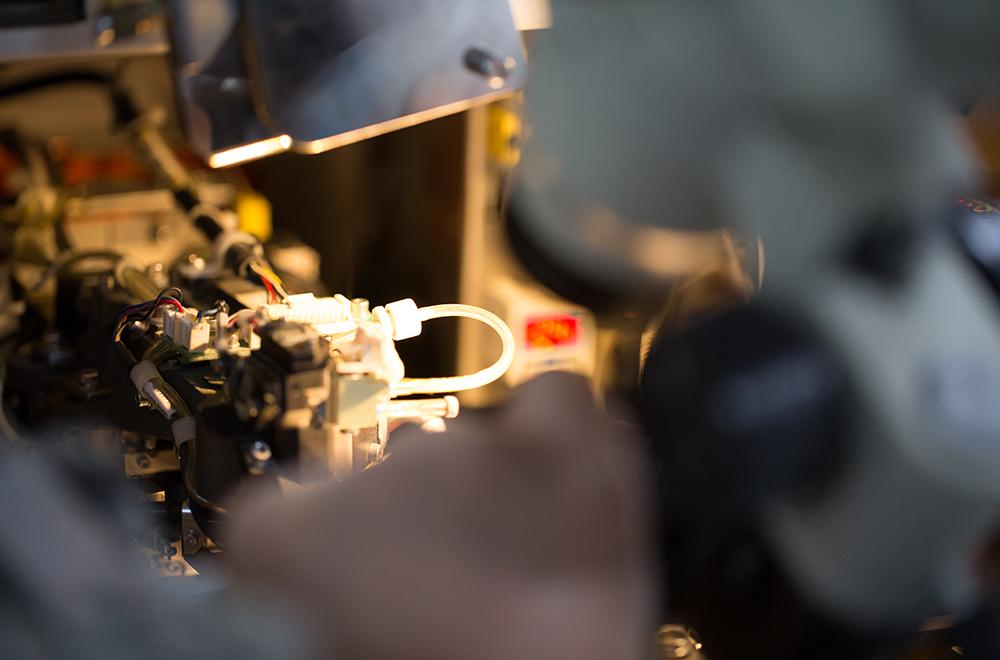

2. Different processing methods:

LED encapsulation

Epoxy resin encapsulation: Epoxy resin’s heat dissipation performance is slightly worse, led easy to become yellow, it can’t anti-UV.

Silicone gel encapsulation: Silicone package has good heat dissipation performance, also anti-UV.

3. Different operating costs determine different profits

- Each LED strip has gone through many links from production progress–sales — after-sales service. Such as preliminary market research, production, advertising, sales, packaging, transportation, after sales, warranty .

- Each link consumes different work and financial resources. And differentfactory has different operating costs, different management efficiency, will affect the product’s factory cost. Therefore, different suppliers of the same product will have different prices. Correctly assessing the size of manufacturer and giving reasonable profits are the prerequisites for maintaining long-term cooperation.

- So one strip price not only just about its product, also including other aspects and so on.

4, LED color selection has tips

- Consistency of LED colors: At present, there are thousands of large and small factories, of course, their technique and LED Spectroscopy Standard are different. Some led factory use Energy Star standard, its color tolerance standard need ≤ 7SDCM, LED divided by its characteristics,some use ERP standard , its color tolerance standard need ≤ 6SDCM, according to the lighting technical requirements to divide LED. also many small packaging factories that do not have strict spectroscopic standards, which makes it difficult to guarantee quality. LEDs that have not undergone spectroscopic separation have poor color consistency specially the White LED easy to have color difference. ( some white color have bluish, and some have Yellowing). The lighting effect is not so good when it is mounted it close to the white wall. The narrower step SDCM LED have, the better color uniform will have, also higher price.

- LED color: In the initial state, the LED needs to be separated and separated. Different colors but different prices. White and green are more difficult to match and separate, so the price is higher than other colors; red, yellow, blue and other colors are easier to separate and separate, and the consistency is better, so the price is slightly cheaper, while white color led used more popular, so now the price is cheaper than colorful type. Special colors such as purple and brown are the most expensive due to color matching.

- Now most SMD used on market: 2835, 3528, 3014, 5050, 5630 and so on, different models, different brightness; the same LED type also has ordinary brightness and higher bright series, different series is also quite different, Therefore, you must clearly know what kind of brightness you needwhen purchasing, then you can choose the most suitable type for you.

5. Different quality standards determine different costs:

Every factory has its own QC standards, and usually their goal is to meet industry standards. Strict product standards mean that high-quality raw materials and high-standard quality control are required. However, in a highly competitive market environment, in order to maintain price advantage in the competition, some factories will take fewer quality inspectors and reduce quality control processes to reduce cost. So different quality standards mean that the difference is the input of personnel and raw materials, and it will also affect the final price.

6. Find the best customized product for you

- Which price is close to its real quality?

- A. Make all the details of customized requirements clearly As mentioned above, the price of LED strips is affected by many factors, including raw materials, producing progress and quality standards. But the most important thing is the choice of LED and PCB raw materials.

- B. Make the LED quality standards clearly

- C. Accept reasonable profit demand from suppliers

- Then best cooperation relation is the win-win business relationship.

- D. Choose the most cost-effective LED classto meeting your own needs,

- E. Avoid unnecessary product customization, maybe you also can find some suitable type from the regular type which close to your need, which can save your tooling cost also make sooner delivery without stock.