How Silicone Neon Bands Are Designed

A good silicone neon light pays attention to high light transmittance, uniform light emission, and resistance to extrusion and durability.The design of the silicone case is crucial.

Let’s take a look at the design of the extruded silicone case.

Silicone case with 4 design structures

- 1 Illuminated surface.

- 2 Internal structure .

- 3 Shearing position.

- 4 Fixing groove

1.NEON design should follow the following principles

- The proportion of the glue and the design of the NEON size determine the light transmittance of the luminous surface. It is necessary to ensure the luminous efficiency and the uniformity of light emission without dark areas.

- Different bending directions require different neon options, positive view neon and side view neon

- The light-emitting surface is designed to be flat and Dome type according to different needs

2.Internal structure design

- The internal filling and luminous surface are made of integrated transparent silicone, which ensures the product’s pressing feeling and enhances the product’s resistance to extrusion and light guide.

- The Hollow area around the LED strip has been tested for dozens of bending tests to determine the optimal gap of 0.5MM. Ensure that the LED chip is not damaged when the product is bent and squeezed.While this Hollow area can’t designed too large, although if design it in large way can save many silicone cost, while the led strip inside easy to move when bend it, can’t be well protected.

3 cutting position design

The cutting position on the back of the LED is made of a transparent silicone glue material, which ensures that the cutting is clearly visible while avoiding light leakage, some neon machine on market only can make 2 colors for neon coating, then its cutting sign won’t be so clear.

4 Grooves design for fixing

Recessed grooves on both sides of the housing for easier of clip installation.

How is the silicone neon extruded

1 Raw material processing

- First, a special raw material processing machine is needed. It converts the silicone raw material into a soft material after high temperature, and then cuts it into a sheet shape suitable for extrusion.

- cooled by air conditioner,

- Finally, the silica gel required for a sheet-like molded appearance is obtained. This kind of silica gel is the raw material for production. It has the characteristics of high temperature resistance, acid and alkali resistance, and non-swelling.

2 extrusion processing

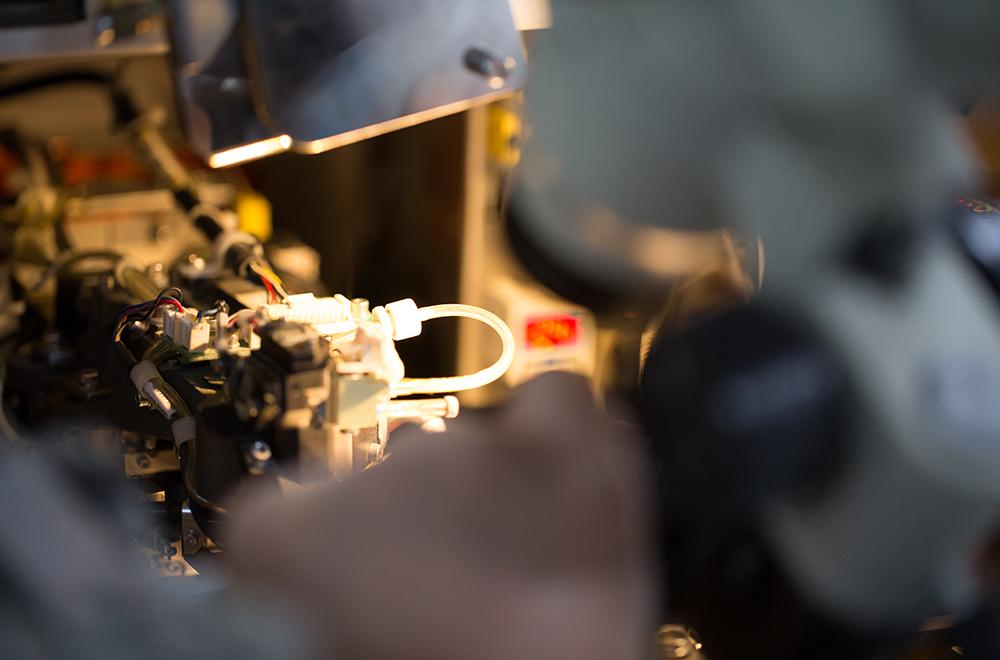

- Put the silica gel into the three different entrance of the extrude machine , mix different toners and put the LED strip into the entrance conveyor of the extruder.

- Some extruded machine only have 2 entrances, so their neon glue only have 2 colors.

- The silicone is heated again in the machine and the silicone is extruded through different tooling shapes, then become the NEON shape as we want.

- The whole strip is covered by whole silicone coating.

3 finished product processing

- NEON is cooled after forming, and then cut to different lengths by a cutting machine, soldering different cable as customer need, sealed with end cap.

- This solder joint needs to be specially designed, like design it in larger area, put large sodering on the back of PCB, must be stable to ensure that the pad will not be broken when pulling NEON.

4 finished product inspection

- Initial power-on inspection, visual inspection, lighting color inspection by QC.

- More standardized factories will use the latest laser engraving machine, laser engraving product information or customer’s LOGO information, etc., designed by computer, only takes a few seconds

5 aging test

- The aging test for neon generally takes 8-12 hours. Different factory standards are different. Some factory take longer time and some have shorter time. Some factories do not do the aging process

- We use special aging test equipment with on/ off switching test, to make sure its reliability .